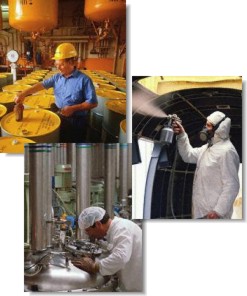

Stewart R. Browne Manufacturing Company utilizes the latest technological advancements to provide Static Grounding and Static Bonding products, Portable Hazardous Location Lighting, and Static Ground Monitoring Systems that meet and exceed our customers’ usages in atmospheres containing explosive gases, vapors and dust, and in which operator safety is the main consideration.

Having developed the first Underwriters Laboratories Listed (UL) hazardous portable lighting products nearly a century ago, we are pleased to share the story of our commitment to delivering excellence in product and service as manufacturers and industry leaders.

History

Stewart R. Browne established the company in 1918, which is now a fourth-generation, family-owned and operated business.

An innovator and entrepreneur, Stewart started out as a salesman who purchased phenolic, an early form of plastic, in bulk for resale. Because the material could withstand exposure to petrochemicals, Stewart recognized the potential for industrial applications and built a New York manufacturing facility that produced piston rings, pump values, gears and other parts.

Interestingly, the Smithsonian Museum in Washington, DC displays Stewart R. Browne’s products from that time period as examples of the earliest plastics. His invention of a modified phenolic compound later became the prototype for our patented TUFFITE™ the light, ultra safe, durable material that we currently use to make the handles of our portable lighting.

Our next innovation was a line of static grounding and bonding clamps and assemblies for companies which produced or handled hazardous flammable materials.

Sons Robert and Stewart Jr., the second generation, carried on their father’s appreciation for ingenuity and quality. During WWII, Stewart Jr. worked closely with the Navy and Air Force to develop explosion-proof lighting for use on aircraft and ships. Since that time, we have fostered a trusted relationship with the military by continuing to provide relevant, reliable solutions. Robert, for instance, took pride in accepting a military honor on behalf of the company for supplying quality products on time during the Viet Nam War. Meanwhile, devising military applications furthered our advancements in safety lighting technology for more general use.

In 1977, about the time Robert decided to retire in Atlanta (where he could enjoy golf year round), sons Alan and James took over as principals and moved the operations from New York to Georgia.

Today, the third and fourth generations remain committed to serving our customers and to leading our industry in manufacturing and distributing Static Grounding and Static Bonding, a wide range of Portable Hazardous Location Lighting, and Static Ground Monitoring Systems for applications in which flammable or combustible materials are present.

Our collaborations with the Office of Homeland Security have additionally enabled us to serve various manufacturing facilities in meeting today’s higher safety and maintenance regulations for the chemical industry.

Designed and manufactured in the USA with the harshest applications and environments in mind, our products have been tested and certified by UL (Underwriters Laboratories) and FM (Factory Mutual) for use when flammable gases, vapors, liquids or dusts are present in such quantities in air that spontaneous flame propagation (explosion) occurs after ignition.

In addition to meeting UL Standards, we have long taken an active role in establishing guidelines as UL committee members. We are also longtime members of the following organizations:

- National Safety Council

- National Fire Protection Agency

- National Association of Chemical Distributors

- National Paint and Coatings Association

Beyond product development, we also offer Value-added Training Programs, Plant Consultations, and Training Materials that assist our customers in complying with OSHA, NFPA and National Electric Code.

With pride, we currently distribute our technology to customers in the US and worldwide, including the Middle East and Europe.

Stewart R. Browne Manufacturing Co. Inc.

Stewart R. Browne Manufacturing Co. Inc.  Click to Enlarge

Click to Enlarge